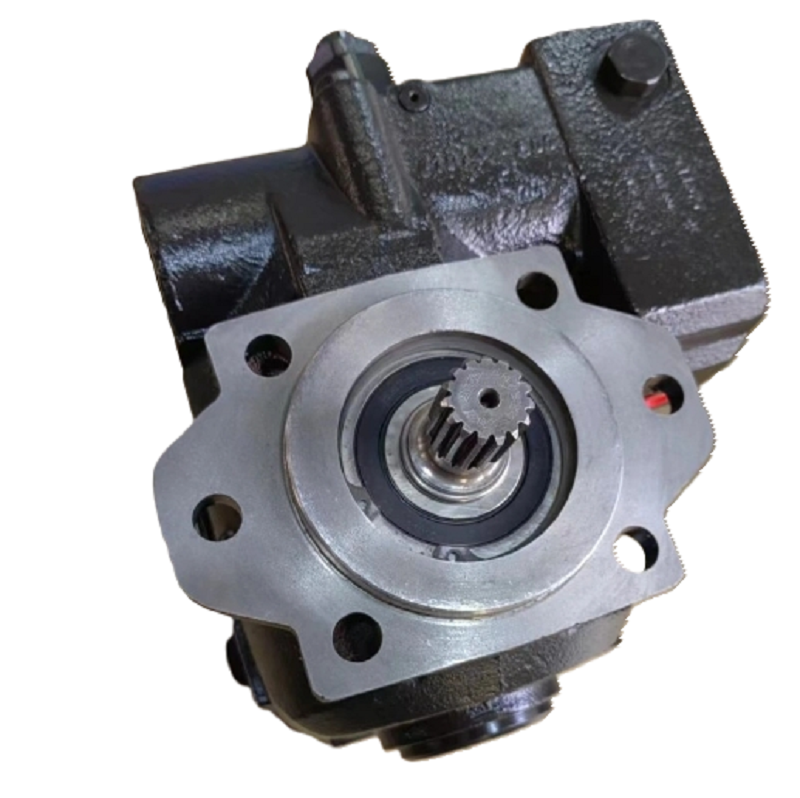

The REXROTH A11VO190LRDH1/11R-NZD12K83 is an axial piston variable displacement pump mainly used in open circuit hydraulic transmission systems. This pump is suitable for use in the field of travelling machinery and is capable of operating under self-priming conditions, as well as under tank pressurization or with a built-in booster pump (centrifugal pump). It has a wide range of control options to meet different operational requirements.

Precautions for use

When using REXROTH A11VO190LRDH1/11R-NZD12K83, the following points should be noted:

Cleanliness requirements: During installation and use, the cleanliness of the system must be ensured. The oil tank and other piping components need to be thoroughly cleaned to avoid impurities entering the hydraulic system and affecting the performance and life of the pump .

Oil temperature: After starting the engine, the temperature rise of the hydraulic oil shall not exceed 100°C within 5 minutes of the hydraulic system working; after 10 minutes of working, the temperature rise shall not exceed 30°C. In a low temperature environment, the engine should be allowed to idle for a period of time until the oil temperature reaches a suitable temperature before loading the work .

Handling and installation: During handling, be careful to avoid collision of the pump control handle and relief valve with hard objects to prevent damage to the seals leading to leakage. When installing, make sure all interfaces and connectors are clean and properly connected .

Casing oiling: After mounting the pump and connecting the system correctly, it is necessary to fill the pump with clean oil and ensure that the rotary body inside the pump is adequately lubricated to prevent wear or burnt rotary elements .

Maintenance and servicing: Check and replace the suction filter element regularly to ensure that the vacuum at the suction port is not less than 0.68 bar absolute pressure. At the same time, the hydraulic oil should be changed regularly, generally recommended to be changed every 500 hours of operation or every six months .

Troubleshooting: If there is a problem with the hydraulic system, non-professionals should not dismantle the pump or motor components without authorization to avoid greater losses. Maintenance should be carried out by professional technicians