Closed hydraulic system implementation

1: any hydraulic system must be safety protection components, closed system is no exception, there should be a safety valve. As the closed system of high and low pressure oil circuit can be switched, so to set up a safety valve in the A, B oil circuit each;

2: Any hydraulic component is an internal leakage. Internal leakage of oil on the one hand, the formation of oil film lubrication between the moving parts of the components for lubrication; on the other hand, the internal leakage of oil can be generated during the operation of the components to bring back to the oil tank, the components play a cooling effect. Therefore, there is an oil drain pipe connected to the oil tank on the pump motor's casing.

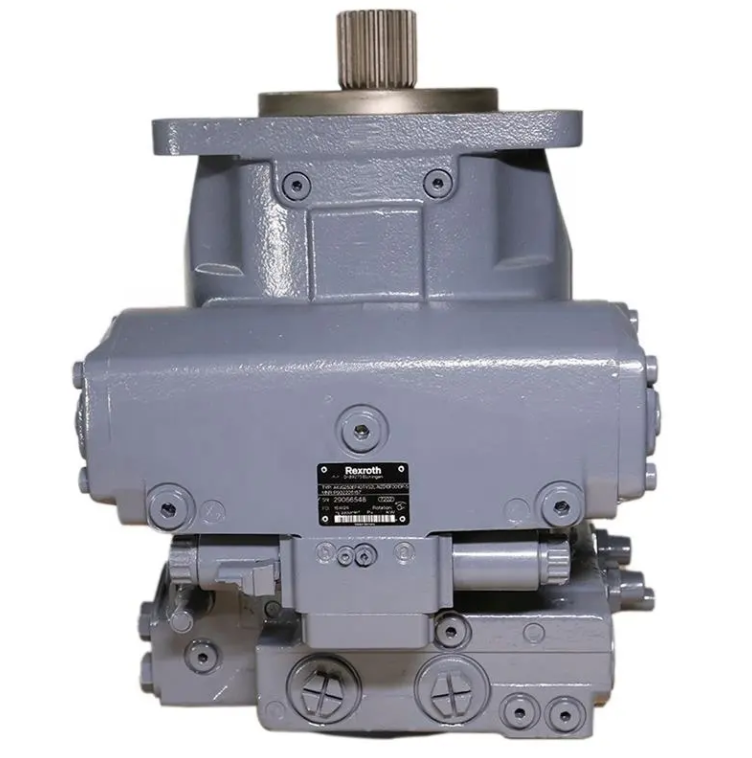

3: the existence of internal oil drain requires a closed circuit to have a corresponding oil replenishment circuit to ensure that the closed circuit is stable and normal work; here the oil replenishment circuit is a typical open hydraulic system. On the oil refill, remind the partners to understand a few points: provide oil refill pump has two forms: built-in and external two. Built into the back of the main pump is usually an internal gear pump (space-saving); external charge pumps are gear pumps, there are piston pumps (mostly constant pressure variable pump). Engineering machinery on the closed system is mostly built-in charge oil pump; industry, mostly external charge oil pump. The displacement of the charge pump is generally about 20% of the displacement of the main pump; the size of the charge pressure, for example, Rexroth A4VG closed-type pump, the charge pressure is generally 25bar, the peak pressure of 40bar, and the lowest charge pressure (instantaneous) can not be lower than 8bar; according to experience, the instantaneous charge pressure can not be lower than 8bar, which is mainly to avoid the sucking of air occurring in a closed-type system. Therefore, in some closed systems (e.g. rotary), due to the severe working conditions, it is usually necessary to add accumulators in order to fully replenish the oil;

4: closed system in the control circuit, closed system in the oil flow direction change is realized through the control pump swash plate over the zero position. Generally, the control oil is provided by the charge pump (in this case, the charge pump can also be called the control pump);

5: The closed circuit has a smaller tank (compared to the open circuit, which only needs to be matched with the charge pump) so the system does not dissipate heat well. In order to accelerate the heat exchange of the system, a flushing valve will be added to the closed system if necessary. The flushing valve can be mounted on the motor, or on the pump, or between the high and low pressure lines of the system.