Pump selection

1, the nature of the liquid, including the name of the liquid medium, physical properties, chemical properties and other properties, physical properties of the temperature c density d, viscosity u, the diameter of solid particles in the medium and the content of gases, etc., which relates to the pressure of the system, the power required to calculate the type of pumps and the appropriate: chemical properties, mainly refers to the chemical corrosiveness and toxicity of the liquid medium is the choice of pump materials and selection of that type of shaft seal type Important basis.

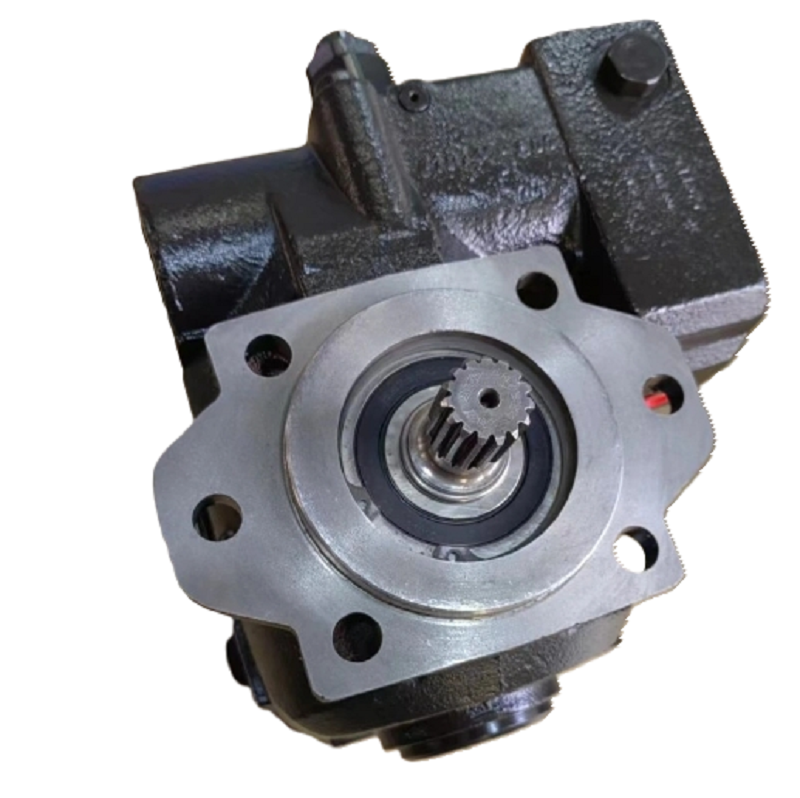

2, the flow rate is one of the important performance data of the selected oil pump, which is directly related to the entire device's production capacity and conveying capacity. Selection of cycloidal gear pumps, based on the maximum flow rate, taking into account the normal flow rate, in the absence of flow rate, usually 1.1 times the normal flow rate as the maximum flow rate. General industrial pumps in the process can be ignored in the piping system leakage, but must be considered when the process changes on the impact of the flow.

3, the pressure required by the device system is another important performance data to select gear oil pumps, generally used to amplify the 5% -10% margin after the pressure to select the type of cycloidal gear pumps. This includes: suction pool pressure, discharge pool pressure, pressure drop in the piping system (pressure loss).

4, the piping arrangement conditions of the oil pump device system refers to the height of the liquid delivery, liquid delivery distance, liquid delivery towards. In order to carry out system pressure calculations and power calibration. Piping system data, if necessary, should also make the device characteristic curve. When designing and arranging the piping, the following matters should be noted:

A, a reasonable choice of pipe diameter, pipe diameter, in the same flow rate, liquid velocity is small, resistance loss is small, but the price is high, pipe diameter is small, will lead to a sharp increase in resistance loss, so that the selected pump pressure increases, with an increase in power, cost and operating costs are increased. Therefore, it should be considered from a technical and economic point of view.

B, the discharge side of the pump must be equipped with valves and check valves. Valves are used to regulate the working condition of the pump, the check valve can prevent the pump from reversing when the liquid flows backwards.

C, the pipeline arrangement should be arranged as straight as possible, minimize the pipeline accessories and minimize the length of the pipeline, must be turned when the bend radius of the elbow should be 3-5 times the diameter of the pipeline, the angle is greater than 90 ℃ as far as possible.

D. The maximum pressure that the discharge pipe and its pipe joints can withstand should be considered.