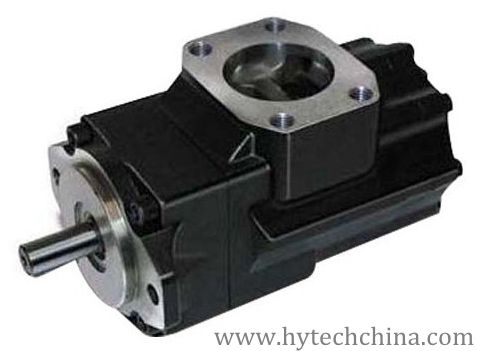

T6 Vane pumps

High pressure and high performance dowel pin type vane pumps are widely used for plastic machinery,casting machinery,metallurgy machinery,pressing machinery,refining machinery,construction machinery,marine-Machinery.

Features

1.With dowel pin vane structure,it can work in high pressure,low noise and long lifetime.

2.This vane pump can fit wide viscosity hydraulic medium,and be xtarted at low temperature and work at high temperature.

3.As the vane pump adopts bilabial structure vane,it has high oil polution resistance and wide sped scope.

T6Series single Pumps

| (F3-) | T6 | C | M | -17 | -1 | R | 00 | A |

| Note | Hydraulic pump column code | Series | Flow code | Shaft type | Rotation | Outlet Positions | Design number | |

| No-marking: Petroleum series oil Emulsification fluid Water glycol-fluid F3:Phoshate ester fluid | T6 series high-pressure vane pump | C | NO:ndustrial M:The car go mechanical type P:Double seal(The car go mechanical type) | 03,05,06,08,10,12,14,17,20,22,25,28,31 | See installation dimensions | (Viewes form shaft end of pump) R-right hand for clockwise L-left hand for counter-clockwise | (Viewed from shaft end of pump) 00-Opposite inlet port 01-Inline with inlet 02-90°CW from inlet 03-90°CW from inlet | A |

| D | 14,17,20,24,28,31,35,38,42,45,50 | |||||||

| E | 42,45,50,52,57,62,66,72,85 |

Technical date

| Series | Flow code (Usgpm) | Geometric displace-ment ml/r | Max.pressure Mpa | Max.speed r/min | Min speed r/min | ||||||

| Antiwear hydraulic oil | General hydraulic oil or phosphate | Water glycol fluid or water-or antiwear hydraulic oil | General hydraulic oil or antiwear hydraulic oil | Water glycol fluid or phoshphare eater fluid or water- oil emulsions | |||||||

| Instant | Continuous | Instant | Continuous | Instant | Continuous | ||||||

| T6C | 03 | 10.8 | 28 | 24.5 | 21 | 17.5 | 17.5 | 14 | 2800 | 1800 | 600 |

| 05 | 17.2 | ||||||||||

| 06 | 21.3 | ||||||||||

| 08 | 26.4 | ||||||||||

| 10 | 34.1 | ||||||||||

| 12 | 37.1 | ||||||||||

| 14 | 46 | ||||||||||

| 17 | 58.3 | ||||||||||

| 20 | 63.8 | ||||||||||

| 22 | 70.3 | ||||||||||

| 25 | 79.3 | 2500 | |||||||||

| 28 | 88.8 | 21 | 16 | 16 | |||||||

| 31 | 100 | ||||||||||

| T6D | 14 | 47.6 | 24.5 | 21 | 21 | 17.5 | 17.5 | 14 | 2500 | 1800 | 600 |

| 17 | 58.2 | ||||||||||

| 20 | 66 | ||||||||||

| 24 | 79.5 | ||||||||||

| 28 | 89.7 | ||||||||||

| 31 | 98.3 | ||||||||||

| 35 | 111 | ||||||||||

| 38 | 120.3 | ||||||||||

| 42 | 136 | 2200 | |||||||||

| 45 | 145 | ||||||||||

| 50 | 158 | 21 | 16 | 16 | |||||||

| T6E | 42 | 132.3 | 24.5 | 21 | 21 | 17.5 | 17.5 | 14 | 2200 | 1800 | 600 |

| 45 | 142.4 | ||||||||||

| 50 | 158.5 | ||||||||||

| 52 | 164.8 | ||||||||||

| 57 | 179.8 | ||||||||||

| 62 | 196.7 | ||||||||||

| 66 | 231.3 | ||||||||||

| 72 | 227.1 | ||||||||||

| 85 | 269 | 9 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 2000 | |||