Features

High efficiency: the cylinder and oil distribution plate adopt spherical oil distribution, which can be automatically centered in rotation, with small circumferential speed and high efficiency.

Durability: The drive shaft can withstand radial loads, increasing service life.

Low noise: design optimization, low noise during operation, enhancing operation comfort.

Precautions for use

Keep hydraulic oil clean: Hydraulic oil should be kept clean in all situations to prevent contaminants from entering the system.

Regularly change the hydraulic oil: It is recommended to change the hydraulic oil for 1000~3000 hours of operation or every six months to maintain the optimal performance of the system.

Maintenance

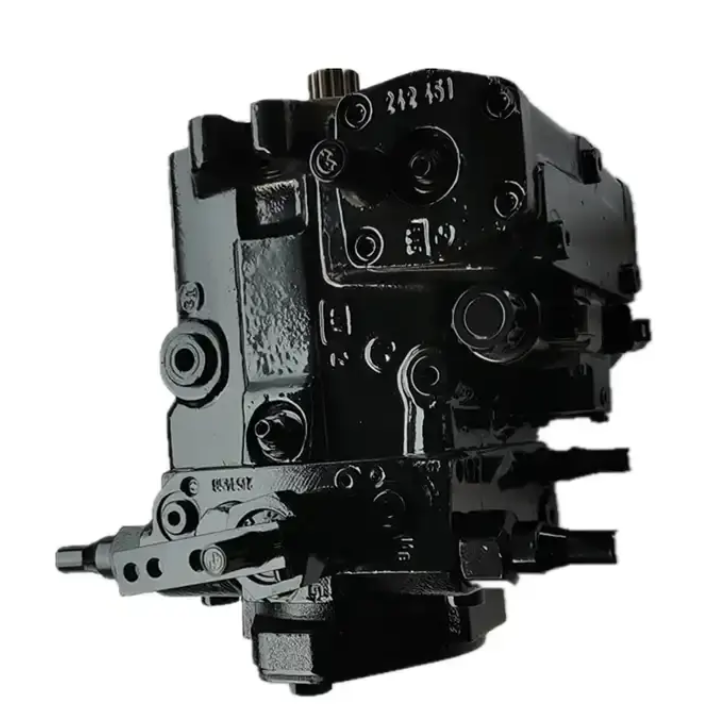

To ensure long-lasting operation and optimum performance of the A4VG125EP2D1/32R-NSF02K69XEH-S, it is recommended that the following maintenance tasks be performed periodically:

Check hydraulic fluid: Check the cleanliness and quality of the hydraulic fluid periodically and replace it if necessary.

Clean the filter screen: Keep the filter screen unobstructed to prevent impurities from clogging and affecting the normal operation of the hydraulic system.

Check seals: Regularly check and replace seals that are badly worn to prevent leakage and loss of efficiency.

Application Scenarios

Due to its outstanding performance and reliability, A4VG125EP2D1/32R-NSF02K69XEH-S is widely used in a variety of industrial fields, including but not limited to:

Construction machinery: such as hydraulic systems for excavators and cranes.

Mining equipment: heavy machinery used in the extraction and processing of ores.

Agricultural equipment: such as power transmission systems for harvesters and tractors.